Engineering Services

Alaşım Metallurgy and Engineering offers solutions based on advanced shaping, heat treatment and quality control techniques for the production of high-quality metal products. In metallurgical processes, various shaping methods are used to achieve appropriate shapes and properties for materials. Techniques such as casting, rolling, extrusion and forging are selected according to the structural requirements and final purpose of each material. The correct application of these methods directly affects the durability, workability and aesthetic properties of the products.

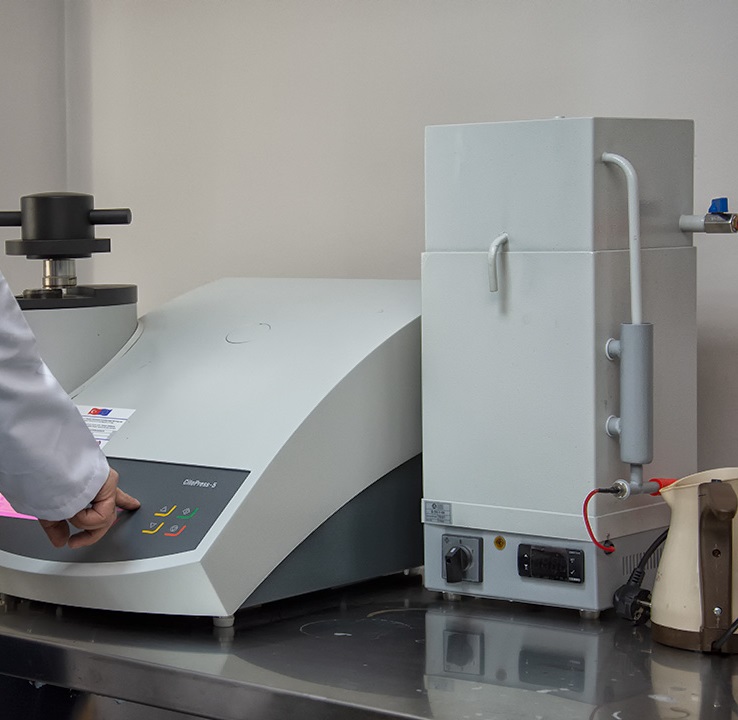

Alloy Metallurgy and Engineering services meticulously apply various shaping methods, heat treatment techniques and quality control parameters to ensure high quality in metalworking processes. Shaping methods such as casting, forging, rolling and extrusion are selected according to the specific needs of each material, ensuring optimum results. Heat treatments such as annealing, hardening and normalization are applied to increase the performance of the alloys produced, thus improving material durability and mechanical properties. In quality control processes, parameters such as chemical composition analysis, mechanical tests and surface roughness measurements are used to ensure that products comply with international standards and customer demands are met at the highest level. These comprehensive processes increase the reliability and efficiency of each product, ensuring customer satisfaction.

Shaping Methods

In alloy metallurgy services, shaping processes are carefully selected according to the type of material and the purpose of production. Casting is carried out by liquidizing the metal and pouring it into molds and is preferred for large, complex parts. Rolling is used to make the metal thin at high temperatures and to produce it in long forms. Extrusion is a common method for converting metals, especially aluminum and steel, into specific profiles. Forging allows the metal to be shaped at high temperatures, increasing its strength. These shaping techniques play an important role in industrial production processes that require high precision and quality.

Heat Treatment Processes

Heat treatment encompasses a series of processes used to improve the mechanical properties of metal. In metallurgical engineering, heat treatment techniques are critical to optimizing the performance of alloys. Annealing is a process used to correct the crystal structure of a metal and to obtain a more homogeneous material. Hardening is a process performed by rapidly cooling the metal, which increases its surface hardness and increases its durability. Similarly, heat treatments such as normalizing and tempering improve the internal structure of the metal and reduce stresses, resulting in more efficient products.

Quality Control Parameters

In Alloy Metallurgy and Engineering services, quality is at the center of all production processes. Quality control is meticulously carried out at every stage and various parameters are used to ensure that products comply with international quality standards. Chemical composition analysis is performed to verify the proportions of elements in the metal, while mechanical tests measure the strength and hardness of the product. In addition, the internal structural properties of the material and surface roughness are also important parts of quality control. Dimensional accuracy is important to test the conformity of the manufactured products to the design. These parameters are meticulously monitored to ensure that the products are safe, efficient and durable.

Compliance with Standards and Certification

Alloy Metallurgy and Engineering strictly adheres to international standards and certifications to ensure the quality of its products. Quality management systems such as ISO 9001, industrial standards such as ASTM, DIN and EN determine the criteria to be followed at every stage of the production process. These standards play a critical role in ensuring quality and increasing the reliability of the products at every stage from material selection to production processes. Quality control processes continuously monitor compliance with these standards and take all necessary measures to meet customer expectations.

Continuous Improvement and Innovation

Alloy Metallurgy and Engineering continuously follows the developments in the sector and uses innovative technologies to continuously improve production processes. R&D activities are of great importance to develop new alloys and increase the performance of existing products. Innovative engineering solutions increase production efficiency, minimize material waste and optimize energy consumption. In addition, investments are made in sustainable production techniques to minimize environmental impacts. In this way, both economic and environmental sustainability are ensured and the most suitable solutions are offered to customer demands.

Customer-Focused Service Approach

Alaşım Metallurgy and Engineering adopts a customer-focused approach and offers customized solutions to each customer's specific needs. Every stage from product design to production is shaped in accordance with customer requirements and quality control parameters are meticulously monitored. Customer satisfaction is achieved not only with the quality of the final product, but also with strong business relationships established with the customer. Our main goals are to establish long-term partnerships and exceed customer expectations by providing reliable, fast and effective solutions in every project.