Alaşım Metallurgy is an engineering company that offers high quality alloys and innovative metallurgy solutions. With our expert staff and modern technology infrastructure, we offer special metallurgy solutions for various sectors; we develop quality, durable and economical materials.

With our long-standing experience in the field of metallurgy, we work with the aim of being a pioneer in the sector in both local and global markets. Keeping customer satisfaction at the forefront, we aim to achieve the best results by using our engineering knowledge in every step from the design phase to production.

Products

We offer quality products that will facilitate your business processes by providing innovative solutions with our customer-oriented approach, enabling you to gain a competitive advantage in your business.

International casting standards are criteria determined for the parts produced in the casting sector to meet the quality, reliability and performance requirements. These standards are developed by organizations such as the American Society for Testing and Materials (ASTM), the International Standards Organization (ISO) and the German Standards Institute (DIN) and define the properties of casting p...

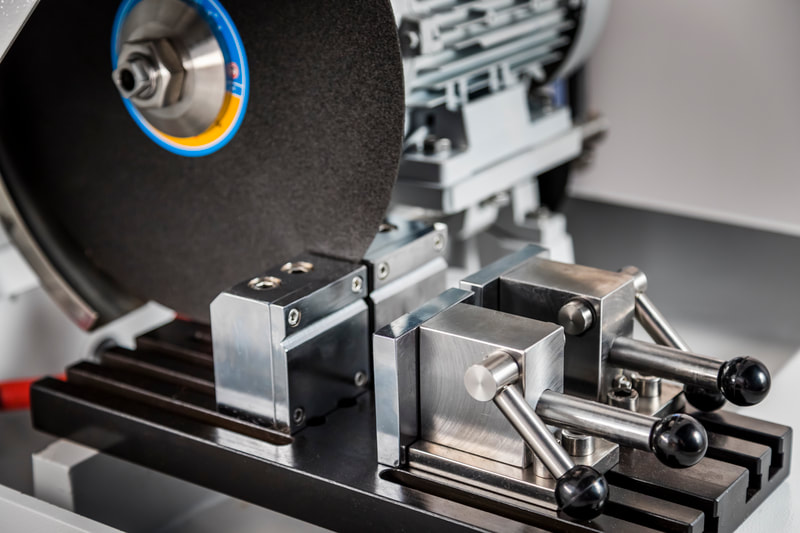

Alaşım Metallurgy and Engineering offers solutions based on advanced shaping, heat treatment and quality control techniques for the production of high-quality metal products. In metallurgical processes, various shaping methods are used to achieve appropriate shapes and properties for materials. Techniques such as casting, rolling, extrusion and forging are selected according to the structural r...

Alaşım Metallurgy has in-depth knowledge and experience in high chromium white cast irons, Ni-Hard cast irons, gray castings, spheroidal castings and alloys, and offers comprehensive consultancy services in these areas. The company provides guidance with its expert staff on material selection, production processes, heat treatments, quality control parameters and appropriate areas of use. It pro...

Alaşım Metallurgy

1. After casting, stresses may occur within the parts, which may cause cracking or deformation in the parts. Annealing or stress relieving heat treatment is usually applied to relieve these stresses. Heat treatment reduces internal stresses by heating and cooling the part in a controlled manner and allows the material to gain a more homogeneous structure. In this way, the performance and durability of the part increases.

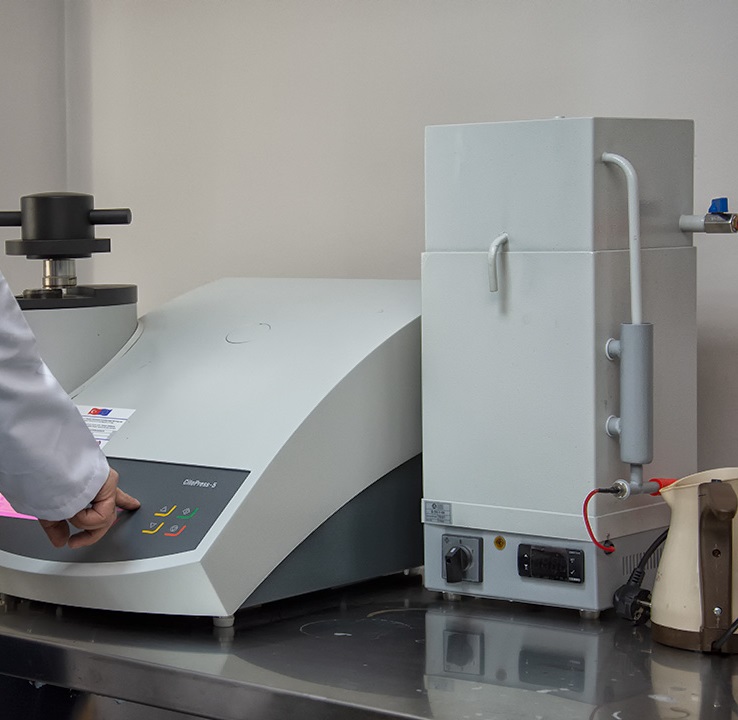

2. Quality control of castings is very important to detect defects that may occur after casting and to ensure compliance with standards. Various methods such as radiographic tests, ultrasonic tests, magnetic particle tests and surface roughness measurements are used in the quality control process. In addition, the chemical composition and mechanical properties of the casting are verified by laboratory analysis.

3. Heat treatment of castings is done to increase the strength, durability and life of the material. Heat treatment improves the internal structure of the metal, reducing the brittleness of the material and increasing its resistance to wear. Heat treatment also eliminates the stresses that occur during casting, allowing a more homogeneous structure to be obtained in the parts.

4. In casting part design, factors such as fluidity of the material, shrinkage and tension should be taken into consideration. The thickness of the part should be balanced and kept at the same thickness if possible. During mold design, air outlets should be left and appropriate transitions should be made to prevent shrinkage gaps. These design details reduce defects that may occur during casting.

Latest News